PFA

PFA is a copolymer of tetrafluoroethylene and perfluoroalkyl vinylether. It is a perfluoro polymer consisting of only carbon atoms and fluorine atoms without any hydrogen atom.

It has the same excellent performance as PTFE in a wide range from extremely low to high temperatures. In addition, it has excellent transparency, mechanical strength at high temperature. It can be molded in the same molding method as general thermoplastic resins.

Grades and Features of AP-Series

| Grades | MFR (g/10 min.) |

Features |

| AP-201 | 20 - 30 | Superior in melt flowability.

Suitable for injection-molded articles that have complex shape, and for ultrafine thin-wire coating (AWG34 - 44). |

| AP-202 | 65 - 80 | Excellent melt flowability.

Suitable for injection-molded articles that have complex shape, and for thin-wire coating (AWG44 - 52). |

| AP-210 | 10 - 17 | Good melt flowability.

Suitable for injection molding. |

| AP-230 | 1.5 - 2.5 | Superior in stress crack resistance.

Suitable for extrusion and transfer molding. |

| AP-201SH | 20 - 30 | High purity grade.

Superior in melt flowability. Suitable for complex shape articles. |

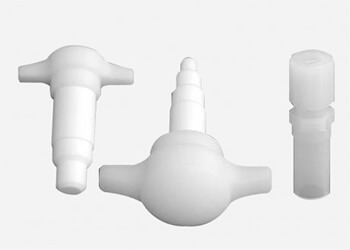

| AP-211SH | 10 - 17 | High purity grade.

Long-term flexibility and good stress crack resistance. Suitable for joints and parts for pumps. |

| AP-215SH | 10 - 17 | High purity grade.

Suitable for injection molding. Suitable for joints and parts for pumps. |

| AP-231SH | 1.5 - 2.5 | High purity grade.

Long-term flexibility and good stress crack resistance. Suitable for extrusion and transfer molding. |

| AP-210AS | 11 - 14 | Anti-static grade.

Suitable for injection molding. |

| AP-230AS | 1.5 - 3.0 | Anti-static grade. Suitable for extrusion molding. |

| AP-230ASL | 1.0 - 2.5 | Anti-static grade.

Suitable for extrusion molding. |