Description:

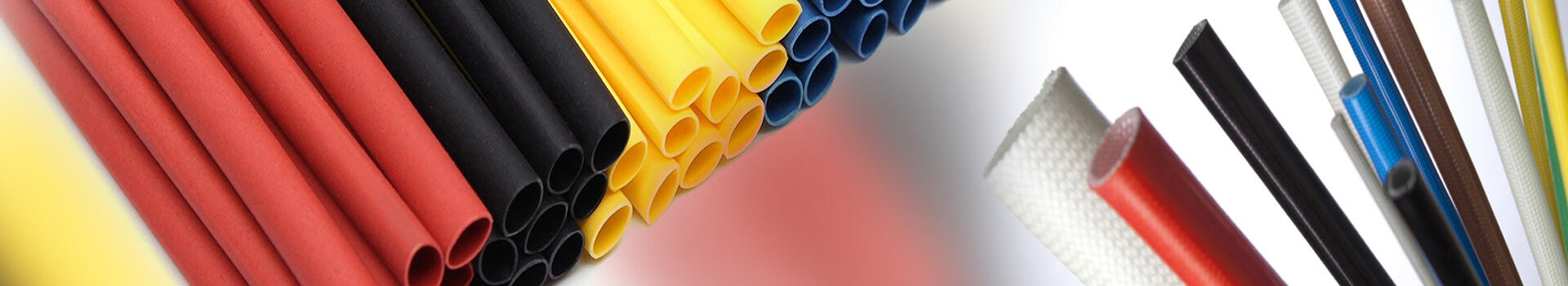

- Made of cross linked polyolefin

- High resistance to tracking, aging and erosion

- Used to offer insulation protection for busbar in switchgear and substation

- Can be supplied in continuous length

- Continuous operation temperature: -45℃ to 105℃

- Shrink temperature: start at 110℃, and fully recovered at 130℃

- Color: yellow, red, green, blue, black

Polyolefin Heat Shrink Bus Bar Sleeve - WMPG

Selection Table

| Property | Test Method | Standard Value |

| Operation Temperature | IEC 216 | -45℃ to 105℃ |

| Tensile Strength | ASTM-D-2671 | ≥10MPa |

| Elongation at Break | ASTM-D-2671 | ≥400% |

| Tensile Strength after Aging | ASTM-D-2671 | ≥8MPa (130℃,168 hrs) |

| Elongation at Break

after Aging |

ASTM-D-2671 | ≥320% (130℃,168 hrs) |

| Dielectric Strength | IEC 60243 | ≥25kV/mm |

| Volume Resistivity | IEC 60093 | ≥1×1014Ω·cm |

| Dielectric Constant | IEC 250 | ≤3.0 |

| Longitudinal Shrinkage | ASTM-D-2671 | ≤10% |

| Eccentricity | ASTM-D-2671 | ≤30% |

| Water Absorption | ISO 62 | ≤0.5% |

| Flammability (Oxygen Index) | IEC 4589 | ≥28 |

| Copper Corrosion | ASTM-D-2671 | No corrosion (130℃,168 hrs) |

| Cold Bend | ASTM-D-2671 | No cracking (-40℃, 4 hrs) |

Selection Table (10 kV heat shrink busbar sleeve)

| Poduct No. | As SSupplied/mm | After Recovered/mm | Standard Length/mm | Standard Length/mm | Suitable for Circular Busbar/mm | ||

| ID (Min) | Wall Thickness | ID (Max) | Wall Thickness(±10%) | ||||

| Ф20 | 20 | 1.2 | 8 | 2.5 | 1000 | 20 | 15 |

| Ф25 | 25 | 1.2 | 11 | 2.5 | 1000 | 25 | 15 |

| Ф30 | 30 | 1.2 | 13 | 2.5 | 1000 | 30 | 20 |

| Ф40 | 40 | 1.2 | 16 | 2.5 | 1000 | 40 | 25 |

| Ф50 | 50 | 1.3 | 18 | 2.8 | 1000 | 50 | 30 |

| Ф60 | 60 | 1.3 | 25 | 2.8 | 1000 | 60 | 40 |

| Ф70 | 70 | 1.3 | 29 | 2.8 | 1000 | 70 | 50 |

| Ф80 | 80 | 1.3 | 34 | 2.8 | 1000 | 80 | 55 |

| Ф100 | 100 | 1.3 | 41 | 2.8 | 1000 | 100 | 75 |

| Ф120 | 120 | 1.3 | 48 | 2.8 | 1000 | 120 | 85 |

| Ф150 | 150 | 1.3 | 62 | 2.8 | 1000 | 150 | 105 |

| Ф180 | 180 | 1.3 | 73 | 2.8 | 1000 | 180 | 120 |

| Ф210 | 210 | 1.3 | 84 | 2.8 | 1000 | 210 | 130 |

| Ф230 | 230 | 1.2 | 85 | 2.8 | 1000 | 230 | 135 |

| Ф250 | 250 | 1.5 | 102 | 3.9 | 1000 | 250 | 140 |

| Ф275 | 275 | 1.4 | 102 | 3.9 | 1000 | 275 | 145 |

| Ф300 | 300 | 1.6 | 110 | 3.9 | 1000 | 300 | 160 |

Selection Table (35 kV Heat Shrink Busbar Sleeve)

| Product No. | As Supplied/mm | After Recovered/mm | Standard Length /mm | Suitable for Rectangular Busbar/mm | Suitable for Circular Busbar/mm | ||

| ID(Min) | Wall Thickness | ID(Max) | Wall Thickness(±5%) | ||||

| Ф20 | 20 | 2.0 | 8 | 4.8 | 1000 | 20 | 15 |

| Ф25 | 25 | 2.0 | 10 | 4.8 | 1000 | 25 | 15 |

| Ф30 | 30 | 2.0 | 15 | 4.8 | 1000 | 30 | 20 |

| Ф40 | 40 | 2.0 | 16 | 4.8 | 1000 | 40 | 25 |

| Ф50 | 50 | 2.0 | 20 | 5.0 | 1000 | 50 | 25 |

| Ф60 | 60 | 2.0 | 25 | 5.2 | 1000 | 60 | 30 |

| Ф70 | 70 | 2.0 | 30 | 5.2 | 1000 | 70 | 35 |

| Ф80 | 80 | 2.0 | 32 | 5.2 | 1000 | 80 | 40 |

| Ф100 | 100 | 2.0 | 40 | 5.2 | 1000 | 100 | 75 |

| Ф120 | 120 | 2.0 | 50 | 5.2 | 1000 | 120 | 85 |

| Ф150 | 150 | 2.0 | 60 | 5.2 | 1000 | 150 | 105 |

| Ф180 | 180 | 2.2 | 70 | 5.6 | 1000 | 180 | 120 |

| Ф210 | 210 | 2.1 | 80 | 5.6 | 1000 | 210 | 130 |